1 北京航空航天大学青岛研究院, 山东 青岛 266100

2 歌尔股份有限公司, 山东 青岛 266100

3 北京航空航天大学, 北京 100191

本文对玻璃晶圆加工过程中常见的三种缺陷类型——颗粒缺陷、气泡缺陷、三角形划痕的散射光强进行分析, 发现不同缺陷结构在空间中有不同的散射光强分布特点, 可以建立缺陷结构与散射光强空间分布的对应关系; 同时针对产线中晶圆表面微米量级缺陷, 进行了不同尺寸颗粒缺陷的散射光强度计算, 得出了微米级别缺陷尺寸与散射光强度之间的关系曲线。从而提出一种非成像缺陷检测方法: 检测获取缺陷散射光强值与空间分布, 利用散射光空间分布结构确定缺陷结构以及利用散射光强计算缺陷尺寸, 从而间接确定缺陷信息, 达到缺陷检测的目的。为晶圆产业应用过程中的缺陷快速检测提供方法参考。

光散射理论 非成像缺陷检测 散射光空间分布 散射光强值 缺陷结构 缺陷尺寸 light scattering theory non-imaging defect detection scattered light spatial distribution scattered light intensity value defect structure defect size

1 北京航空航天大学青岛研究院仪器科学与光电工程学院, 山东 青岛 266104

2 北京航空航天大学仪器科学与光电工程学院, 北京 100191

3 歌尔科技有限公司, 山东 青岛 266104

为了抑制在头戴式增强现实显示系统中激光扫描(LBS)与光栅光波导直接耦合时产生的带斑(Banding)现象并改善系统的最终成像效果,首先介绍了Banding现象,分析讨论了Banding现象产生的具体原因。随后,提出了一种加入扩散片的扩束抑制方法,并通过扩束光路结构验证了其可行性。针对抑制方案进行了小尺寸、大视场中继光路的设计优化,以满足其在头戴式增强现实显示系统中的应用。本设计的系统总长小于25 mm,在截止频率43 lp/mm处,前端与后端各视场的调制传递函数值均大于0.3,畸变均小于±2.2%,满足设计的各项指标需求。所提方法可以有效抑制LBS与光栅光波导配合使用过程中的Banding现象,因此为基于LBS的头戴式增强现实显示系统的研究提供了一定的参考价值,具有潜在的应用前景。

几何光学 增强现实 激光扫描显示 Banding现象 光学设计 激光与光电子学进展

2020, 57(13): 130801

Author Affiliations

Abstract

1 National Laboratory on High Power Laser and Physics, Shanghai Institute of Optics and Fine Mechanics, Chinese Academy of Sciences, Shanghai 201800, China

2 Shanghai Institute of Laser Plasma, Shanghai 201800, China

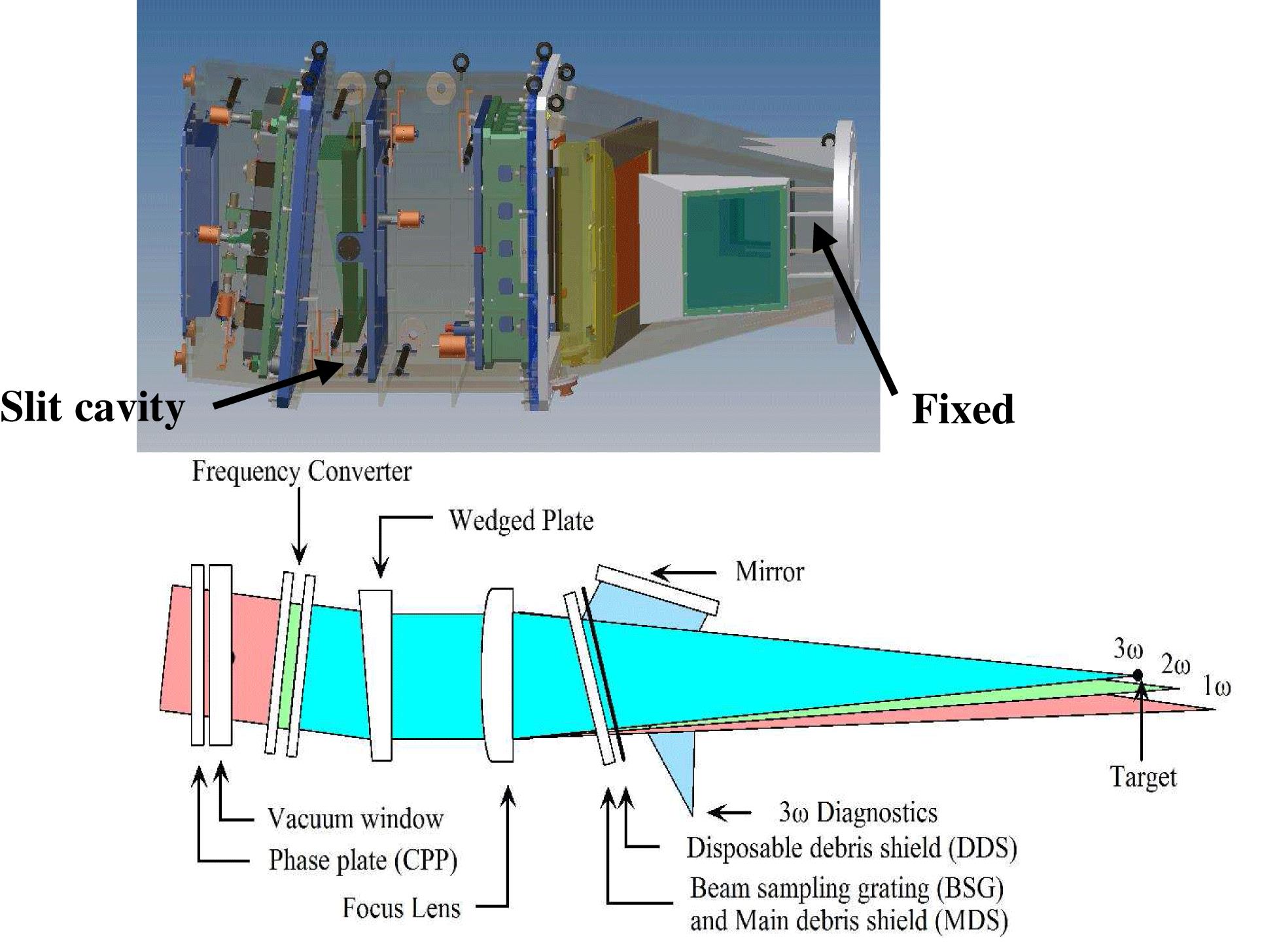

In high power laser facility for inertial confinement fusion research, final optics assembly (FOA) plays a critical role in the frequency conversion, beam focusing, color separation, beam sampling and debris shielding. The design and performance of FOA in SG-II Upgrade laser facility are mainly introduced here. Due to the limited space and short focal length, a coaxial aspheric wedged focus lens is designed and applied in the FOA configuration. Then the ghost image analysis, the focus characteristic analysis, the B integral control design and the optomechanical design are carried out in the FOA design phase. In order to ensure the FOA performance, two key technologies are developed including measurement and adjustment technique of the wedged focus lens and the stray light management technique based on ground glass. Experimental results show that the design specifications including laser fluence, frequency conversion efficiency and perforation efficiency of the focus spot have been achieved, which meet the requirements of physical experiments well.

final optics assembly high power laser facility inertial confinement fusion. High Power Laser Science and Engineering

2018, 6(2): 02000e14

Author Affiliations

Abstract

1 National Laboratory on High Power Laser and Physics, Shanghai Institute of Optics and Fine Mechanics, Chinese Academy of Sciences, Shanghai 201800, China

2 Key Laboratory of High Power Laser and Physics, Shanghai Institute of Optics and Fine Mechanics, Chinese Academy of Sciences, Shanghai 201800, China

3 Shanghai Institute of Laser Plasma, China Academy of Engineering Physics, Shanghai 201800, China

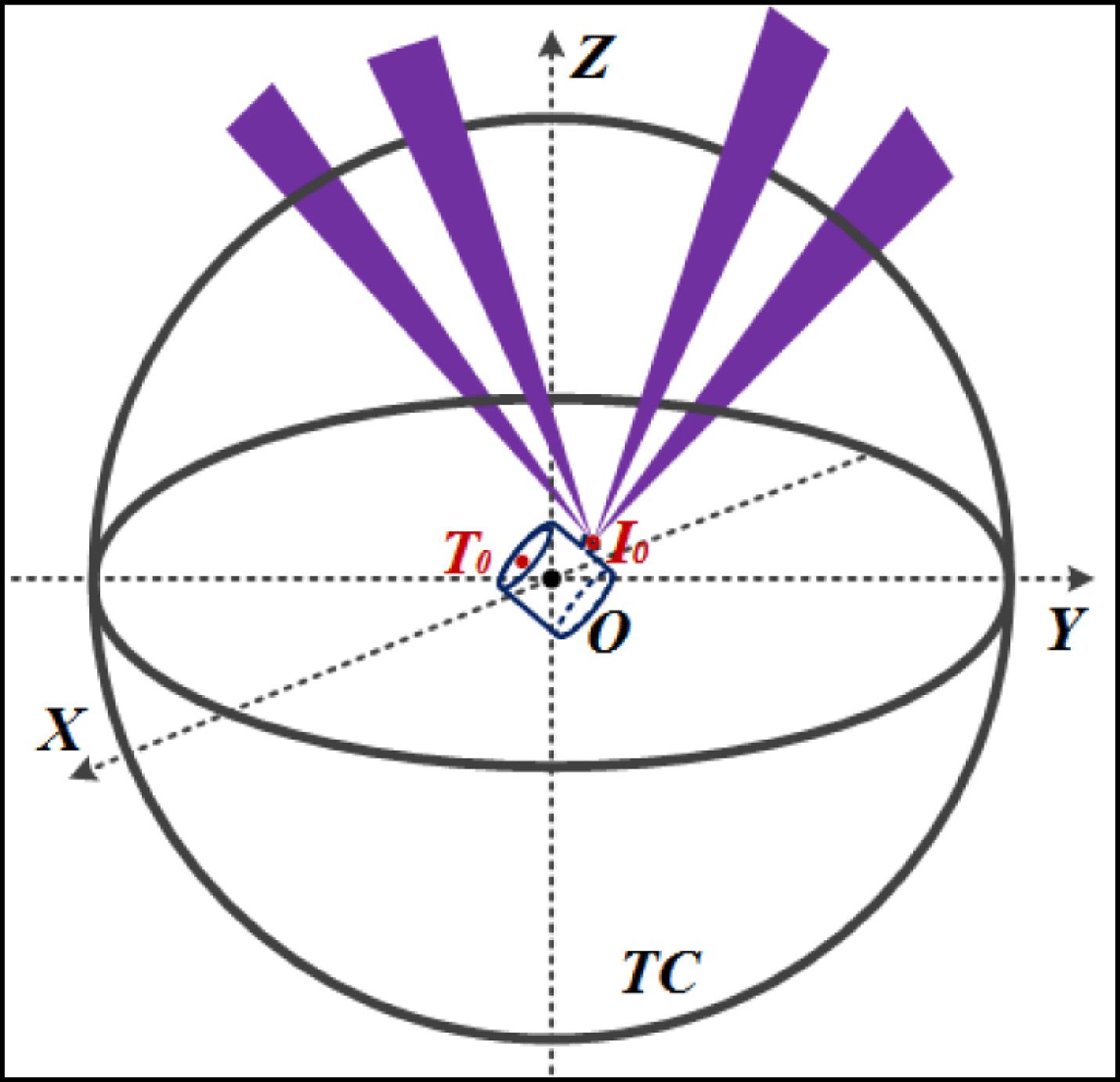

The Shen-Guang II Upgrade (SG-II-U) laser facility consists of eight high-power nanosecond laser beams and one short-pulse picosecond petawatt laser. It is designed for the study of inertial confinement fusion (ICF), especially for conducting fast ignition (FI) research in China and other basic science experiments. To perform FI successfully with hohlraum targets containing a golden cone, the long-pulse beam and cylindrical hohlraum as well as the short-pulse beam and cone target alignment must satisfy tight specifications (30 and $20~\unicode[STIX]{x03BC}\text{m}$ rms for each case). To explore new ICF ignition targets with six laser entrance holes (LEHs), a rotation sensor was adapted to meet the requirements of a three-dimensional target and correct beam alignment. In this paper, the strategy for aligning the nanosecond beam based on target alignment sensor (TAS) is introduced and improved to meet requirements of the picosecond lasers and the new six LEHs hohlraum targets in the SG-II-U facility. The expected performance of the alignment system is presented, and the alignment error is also discussed.

laser drivers petawatt lasers spherical hohlraum target alignment target area High Power Laser Science and Engineering

2018, 6(1): 01000e10

Author Affiliations

Abstract

National Laboratory on High Power Laser and Physics, Shanghai Institute of Optics and Fine Mechanics, Chinese Academy of Science, Shanghai 201800, China

With the increasing number of laser beams, the main difficulty in arranging beam guiding systems (BGSs) involves determining the corresponding relationships between the output and input ports to realize the identified light path length of all beams. Given the basic constraints of geometric arrangement, a BGS model is established, and a base-line algorithm is proposed to address the difficulty mentioned above. Boundary conditions of target area and target chamber are discussed to increase the number of laser beams, and a maximum value exists for a specific target area. Finally, the compatibility of a cylindrical hohlraum target chamber with a spherical hohlraum is analyzed, and a moveable final optics assembly is proposed to execute the switch between the two different targets.

beam guiding system laser drivers spherical hohlraum target areas Collection Of theses on high power laser and plasma physics

2015, 13(1): e12

Author Affiliations

Abstract

1 中国科学院上海光学精密机械研究所高功率激光物理联合实验室, 上海 201800

2 中国工程物理研究院上海激光等离子体研究所, 上海 201800

The wedge-shaped lens is the key and special optical component of the final optics assembly (FOA) in high power laser facility. The wedge-shaped lens wedge angle measurement plays a remarkable role in focusing performance of high power laser. If processing angle and work attitude of the wedge-shaped lens deviate from the specific work angle, big surface deviation will be introduced into the FOA. Special shape of the wedge-shaped lens is not conducive to the measurements of the transmission profile and wedge angle. A set of wedge-shaped lens measurement adjustment programmes is proposed, including measurement of the wedge-shaped lens in processing process, and off-line measurement of wedge-shaped lens during alignment and on-line measurement during the debugging process. The scheme can ensure the processing precision and working attitude of the wedge-shaped lens, guarantee the beam quality and the positioning accuracy of the FOA components of high power laser system.

光学器件 高功率激光装置 终端光学组件 楔形透镜 楔角误差 塔差 optical devices high power laser facility final optics assembly wedge-shaped lens wedge angle error tower error Collection Of theses on high power laser and plasma physics

2015, 13(1): 0408006

Author Affiliations

Abstract

National Laboratory on High Power Laser and Physics, Shanghai Institute of Optics and Fine Mechanics, Chinese Academy of Science, Shanghai 201800, China

With the increasing number of laser beams, the main difficulty in arranging beam guiding systems (BGSs) involves determining the corresponding relationships between the output and input ports to realize the identified light path length of all beams. Given the basic constraints of geometric arrangement, a BGS model is established, and a base-line algorithm is proposed to address the difficulty mentioned above. Boundary conditions of target area and target chamber are discussed to increase the number of laser beams, and a maximum value exists for a specific target area. Finally, the compatibility of a cylindrical hohlraum target chamber with a spherical hohlraum is analyzed, and a moveable final optics assembly is proposed to execute the switch between the two different targets.

beam guiding system laser drivers spherical hohlraum target areas High Power Laser Science and Engineering

2015, 3(1): e12

Author Affiliations

Abstract

1 Shanghai Institute of Optics and Fine Mechanics, Chinese Academy of Sciences, No. 390, Qinghe Road, Jiading District, Shanghai 201800, China

2 University of Chinese Academy of Sciences, No. 19A Yuquan Road, Beijing 100049, China

The Shenguang-II Upgrade (SG-II Up) facility is an under-construction high-power laser driver with eight beams, 24 kJ energy, 3 ns pulse duration and ultraviolet laser output, in the Shanghai Institute of Optics and Fine Mechanics, China. The prototype design and experimental research of the prototype final optics assembly (FOA), which is one of the most important parts of the SG-II Up facility, have been completed on the ninth beam of the SG-II facility. Thirty-three shots were fired using 1-! energy from 1000 to 4500 J and 3-! energy from 500 to 2403 J with a 3 ns square pulse. During the experiments, emphasis was given to the process of optical damage and to the effects of clean-gas control. A numerical model of the FOA generated by the Integrated Computer Engineering and Manufacturing code for Computational Fluid Dynamics (ICEMCFD) demonstrated that a flux within 1–5 l s-1 and a 180 s period is effectual to avoid contaminant sputtering to the optics. The presence of surface ‘mooning’ damage and surface spots located outside the clear aperture are induced by contaminants such as wire, silica gel and millimeter order fiber and metal.

Final Optics Assembly optical damage SG-II-Up High Power Laser Science and Engineering

2015, 3(1): 010000e7

1 中国科学院上海光学精密机械研究所高功率激光物理联合实验室, 上海 201800

2 中国工程物理研究院上海激光等离子体研究所, 上海 201800

楔形透镜是高功率激光系统终端光学组件的关键元件,也是较为特殊的光学元件,楔形透镜的楔角测量关系着高功率激光的聚焦性能。终端组件中楔形透镜的加工角度、工作姿态一旦偏离了特定的工作角度,终端组件会引入大的面形偏差,楔形透镜特殊的形状不利于楔形透镜面形、楔角的测量。提出了一整套楔形透镜测量调整方案,包括楔形透镜加工过程中的测量方案,楔形透镜安装过程中的离线测量与调整方案,以及终端组件上线调试过程中的在线调试测量方案。该套方案的实施能够保证楔形透镜的加工精度,及组件中楔形透镜能够工作在最佳工作姿态,保障了高功率激光系统终端组件的光束质量和定位精度。

光学器件 高功率激光装置 终端光学组件 楔形透镜 楔角误差 塔差

1 中国科学院 上海光学精密机械研究所, 高功率激光物理联合实验室, 上海 201800

2 中国科学院大学, 北京 100049

为了提高熔石英元件表面抗激光损伤阈值, 利用超声波辅助HF酸研究平滑光学元件表面缺陷形貌和去除刻蚀后残留物效果, 通过扫描电子显微镜电镜和原子力显微镜记录表面形貌结构, 以及单脉冲激光辐照测试抗损伤阈值确定实验参数。研究表明, 超声波场的引入能催化HF酸的刻蚀速率、提高钝化效果并且更易剥离嵌入的亚μm级杂质粒子。经过实验测试, 获得了熔石英类元件相匹配的超声辅助HF酸刻蚀实验参数, 研究结果对应用超声波辅助HF酸研究熔石英表面抗激光损伤有重要意义。

激光光学 熔石英 超声波 损伤阈值 化学刻蚀 laser optics fused silica ultrasonic damage threshold chemical etching 强激光与粒子束

2015, 27(1): 012001